BMC VS PVC Building Materials

The ceiling and wallboard materials have been developed for more than ten years, and the technology is constantly being updated. The PVC ceiling is not resistant to high temperature, and it is easy to deform in a hot environment. The plastic steel plate is improved from the second generation of ceiling material PVC, which has the advantages of lower price, good thermal insulation and sound insulation, rich color and easy installation and installation. However, according to the supervision and inspection results of the plastic plate market by the Supervisory Office, the quality pass rate of plastic steel products on the market is only 40%. The phenomenon of "water injection" in bending strength, coating thickness, and alkali resistance is serious. Moreover, the plastic steel sheet has low strength, is easily twisted, is not environmentally friendly, has poor weather resistance, and releases toxic gases when burned. The physical properties of the BMC composite ceiling are very stable, and will not be deformed even if the water is long. The BMC ceiling is an excellent material for the ceiling and naturalization board in terms of strength and rigidity.BMC Bulk Molding Compound Material Adavantages

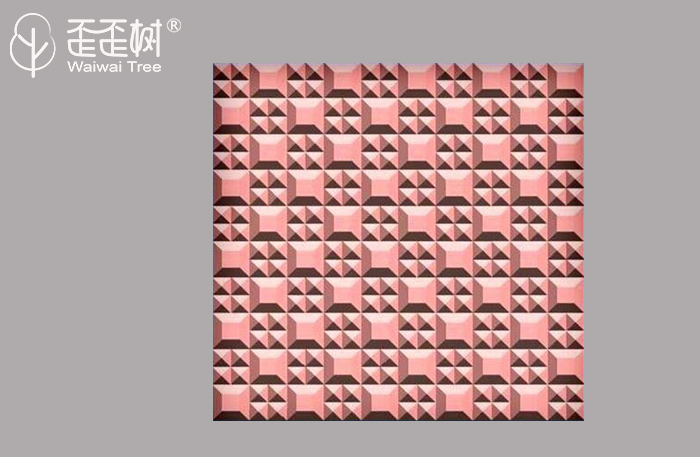

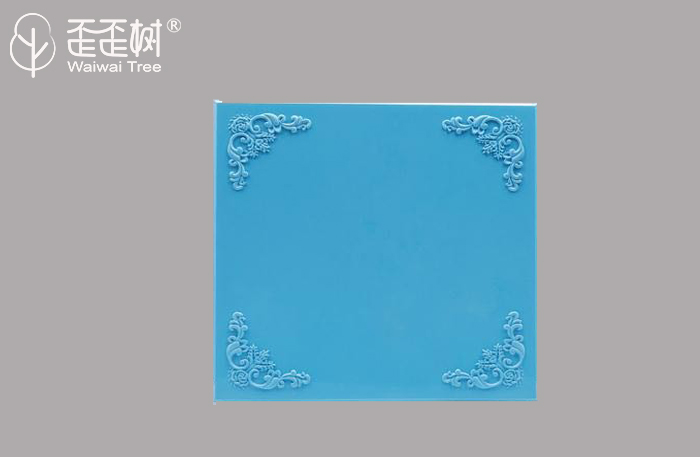

The ceiling uses BMC bulk molding compound as a completely environmentally friendly material, and its advantages are numerous, as follows:Beautiful, moisture-proof, easy to clean, excellent flame retardant effect, high strength, long life, environmental protection, easy installation, moisture-proof and waterproof, flame retardant, thermal insulation, corrosion resistance, tight connection, oxidation resistance, aging resistance, no deformation, high strength, light and tough, easy to install.

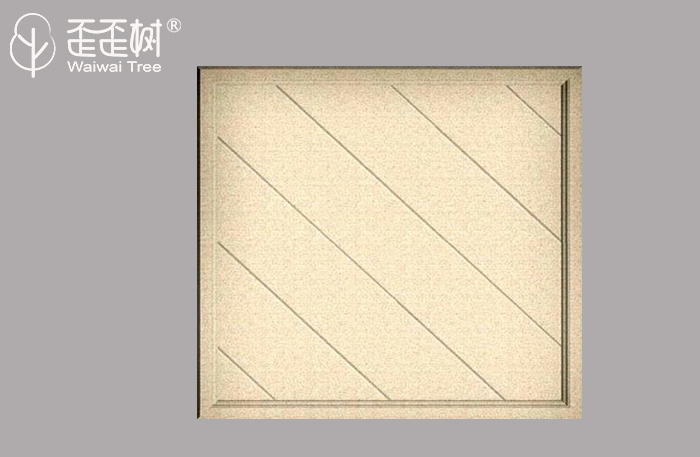

It has natural texture and wooden texture, various colors, natural beauty, various specifications, size, shape, thickness, the same processing performance as logs, high environmental protection, no pollution, recyclability, simple installation, convenient construction. No cracking, no expansion, no deformation, no maintenance and repair, easy to clean, anti-aging, waterproof, moisture-proof, mildew-proof, anti-corrosion, anti-insect, anti-termite, effective flame retardant, anti-aging and thermal insulation. What is important is the low material cost of BMC molding compound, making it a cost-effective ceiling material for ceilings such as steel-plastic panels, aluminum gussets, and aluminum alloys.

◆ The visual effect is soft, feels good, high strength, flame retardant, fireproof, and has strong weather resistance.

◆ Excellent insulation and heat insulation performance, which overcomes the poor thermal insulation performance of traditional ceilings.

◆ Good water resistance, no corrosion, deformation, fading and other undesirable phenomena in a humid environment.

◆ Excellent sound absorption, it is a good sound insulation material, suitable for public places such as medium and high-grade office buildings and large conference halls.

GET IN TOUCH

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский العربية

العربية tiếng việt

tiếng việt Polska

Polska română

română