SMC and BMC development is driven by automotive industry by a large portion. SMC and BMC products is motivated under the rising gas fare and environment problems. Framing parts are one of SMC and BMC products employed in auto industry. SMC and BMC frame moulding contributes to professionalized, automated, high efficient production. We are a frame mold supplier. Inverter frame mold is available for you.

SMC/BMC is ideal substitute for metal as frame working in high temperature conditions. SMC and BMC are highly mouldable, of high strength and lightweight. Thermoset composite material is a perfect solution to gain flame resistance, high strength and light weight. SMC and BMC meet the design purposes of strength, shape and safety.

The superior properties make SMC and BMC composite materials more and more popular in jumbo and highly precise parts. But direct contact of mould with composite materials in moulding process might cause the mould to be out of shape, which will influence the size and shape of part piece.

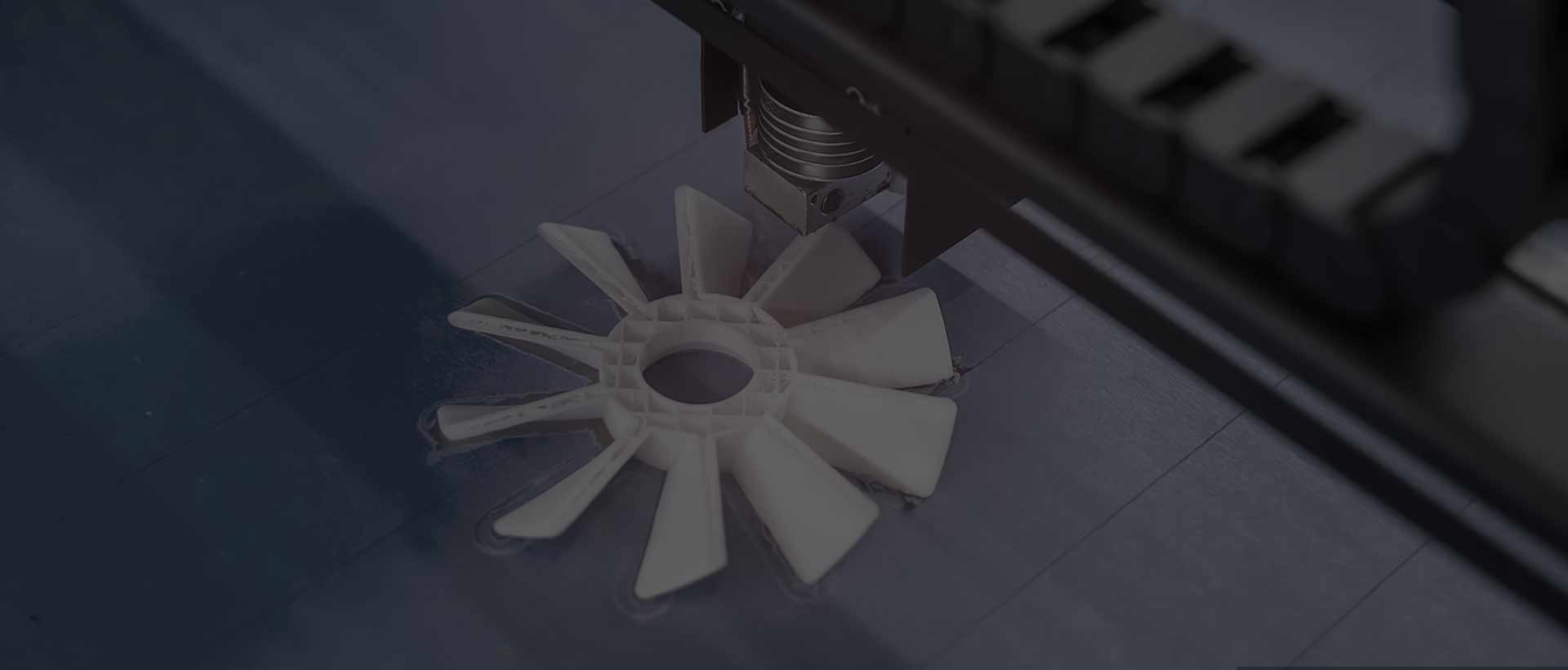

As a professional frame moulding supplier, we perform modeling in design process, which will improve the efficiency and precision of mould design and make mould better align with the composite parts moulding requirements. Dimensional and springback compensation is considered as well during design to deliver high precision mould.

Strong plasticity, precise size, high insulation and high temperature resistance. The mold has a high degree of standardization, reasonable flow channel design, small cavity pressure, balanced temperature, no handle, and low power consumption.