-

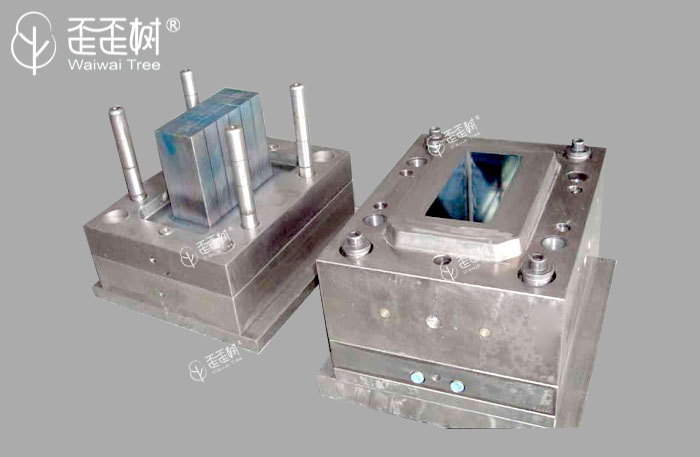

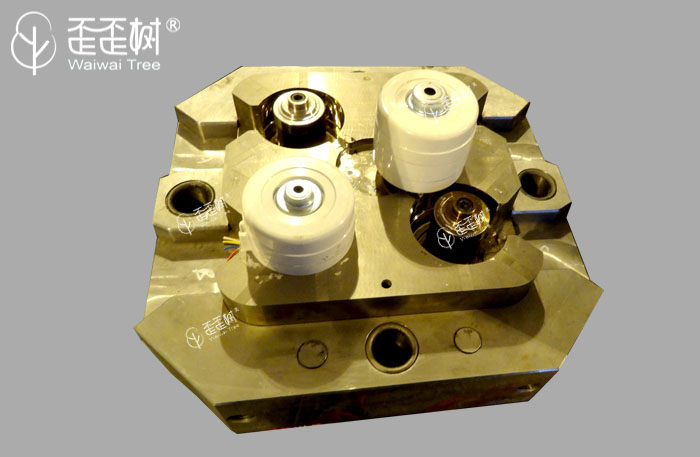

Motor Mold

- Servo Motor Mold

- BMC Plastic-Envelop Motor Mould

- Over Mouding

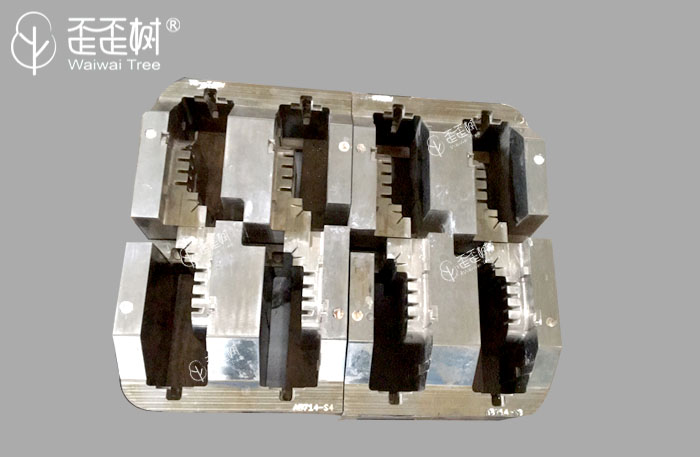

- BMC Rotor Mould

- BMC Stator Mould

- Air Conditioner Motor Mould

- Refrigerator Motor Mould

- Washing Machine Motor Mould

- DC Motor Mold

- AC Motor Mould

- Automotive Motor Mould

- Power/Electic Tool Rotor Mould

- Hood Motor Mould

- Motor End Cap Mould

- Motor Bracket Mould

- Motor Mold Supplier

- Motor Mold Specification

- Factors Deciding the Quality of a Motor Mould

- SMC Cable Braket Moulding

- High Voltage Electrical Product Mould

- Low Voltage Electrical Appliance Mould

- Auto Parts Mould

- SMC Antenna Reflector Mould

- Insulation Mold

- Insulated Shell Mould

- Insulation Board Mould

- Shell Moulding

- Household Mould

- Flange Molding

- Frame Moulding

- Inquire About Our Motor Molds

- Difference Between SMC and BMC

- SMC Material & Compression Molding Processes

- BMC Material & Injection Molding Processes

- BMC/SMC Mould Manufacturing

-

BMC/SMC Motor

- BMC/SMC Motors Manufacturer

- What is Bulk Molding Compound (BMC)

- What Are BMC Electric Motors

- Advantages of Using BMC in Electric Motor Production

- What is Sheet Molding Compound (SMC) Motor

- Advantages and Applications of SMC Motor

- SMC Motor Manufacturing Process

- Servo Motor

- Plastic-Envelop Motor

- Over Moulding Products

- BMC Rotor

- BMC Stator

- Air Conditioner Motor

- Refrigerator Motor

- Washing Machine Motor

- DC Motor

- AC Motor

- Automotive Motor

- Power Tool Rotor

- Hood Motor

- Motor End Cap

- Motor Bracket

- SMC Cable Braket

- High-Voltage Electrical Products

- Low-Voltage Electrical Products

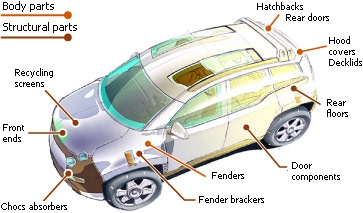

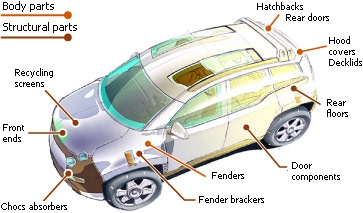

- SMC Auto Parts

- SMC/BMC Antenna Reflector

- BMC/SMC Insulation

- Insulated Shell

- SMC/BMC Insulation Board

- SMC/BMC Shell

- SMC/BMC Household Goods

- SMC/BMC Flange

- SMC/BMC Framework

- BMC, SMC, GRP, GFK Ceiling

- BMC, SMC, GRP, GFK Wall Panel

- BMC, SMC, GRP, GFK Building & Decoration Materials

- BMC, SMC, GRP, GFK Roof Tiles

- Inquire About Our BMC/SMC Products

- What is SMC Plastic?

- About BMC/SMC Products

-

With the continuous advancement of household appliance technology, washing machine products are not only pursuing energy efficiency, quietness, and durability, but also demanding higher requirements f...

-

2025/08/13 SMC Injection Molding: An Efficient Technological Path for Composite Material Manufacturing

2025/08/13 SMC Injection Molding: An Efficient Technological Path for Composite Material ManufacturingWhat is SMC Injection Molding?SMC is the abbreviation for "Sheet Molding Compound", which is a sheet molding compound made from a mix of thermosetting resin (such as unsaturated polyester re...

Cars, buses, trucks, transport and special vehicles

• Weight:

Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same strength. The stroke is increased and the fuel consumption is greatly reduced.

• Stable shape:

SMC's thermal expansion coefficient, CLTE, is low enough to withstand engine temperatures and summer temperatures, making it suitable for automotive panel covers, engine covers and roof panels.

• Surface treatment:

SMC body panels have excellent surface quality, are as easy to paint as traditional steel panels, and have a better texture.

• Production cycle:

SMCinjection molding is highly malleable, greatly reducing the number of components required for assembly, and thermoset materials reduce design and production time.

• Safety:

SMC injection molding has a strong insulation effect, 1mm can withstand tens of thousands of volts, and solves the insulation requirements in the automotive field.

• Durability:

SMC's superior UV protection, aging resistance, acid and alkali resistance, waterproof and moisture resistance, greatly improve the service life.

• Weight:

Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same strength. The stroke is increased and the fuel consumption is greatly reduced.

• Stable shape:

SMC's thermal expansion coefficient, CLTE, is low enough to withstand engine temperatures and summer temperatures, making it suitable for automotive panel covers, engine covers and roof panels.

• Surface treatment:

SMC body panels have excellent surface quality, are as easy to paint as traditional steel panels, and have a better texture.

• Production cycle:

SMCinjection molding is highly malleable, greatly reducing the number of components required for assembly, and thermoset materials reduce design and production time.

• Safety:

SMC injection molding has a strong insulation effect, 1mm can withstand tens of thousands of volts, and solves the insulation requirements in the automotive field.

• Durability:

SMC's superior UV protection, aging resistance, acid and alkali resistance, waterproof and moisture resistance, greatly improve the service life.

Related Products:

-

View Details >

Auto Parts Mould

View Details >

Auto Parts Mould

Auto Parts Mould sloves the problem of ligh-weight, aging and other leakage issues as well as reduces more costs but improves the quality.

GET IN TOUCH

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский العربية

العربية tiếng việt

tiếng việt Polska

Polska română

română